Gallery of Wooster Brush

Gallery

Newspaper Article Citations

1870s

- September 15, 1870: "Wooster Brush Factory - A Foss' Brush Factory", Wayne County Democrat.

- December 01, 1887: "A Visit To The Wooster Brush Works: An Institution That Never Shuts Down, But is Kept Busy All the Year", Wooster Republican, p. 4.

1890s

- October 29, 1890: "James G. Blaine. That Magnetic Name Which a Nation Reveres: The Sixteenth District Gives Him a Warm Greeting at Canton: Fifty Thousand Visitors and the Entire Population of Stark County's Capitol Outdo the Records for Public Gatherings: Bad Weather Disarranges the Programme but does not Dampen Republican Enthusiasm", Wooster Republican, p. 1.

- January 26, 1893: "Wooster Booming: Her Business Men - Her Industries - Her Wide-Awake Manufacturers - Her Future Prosperity", The Jacksonian, p. 3.

- May 09, 1893: "Double the Force Would a Wooster Works Employ If It Had Room", Wooster Daily Republican, p. 4.

- May 16, 1893: "The Case Plainly Stated", Wooster Daily Republican, p. 2.

- July 05, 1893: "Here and There", Wooster Daily Republican, p. 1.

- July 29, 1893: "Brush Works Addition - Contract Let and Work Started", Wooster Daily Republican, p. 1.

- December 16, 1896: "Wooster Brushes: Brisk Business for a Local Factory", Wooster Republican, p. 0.

- July 28, 1897: "Brush Works Prospects Bright", Wooster Republican, p. 2.

1900s

- February 11, 1903: "Brushmakers Strike", Wayne County Democrat, p. 0.

- June 03, 1903: "Work on Remoldeling the Brush Works Factory Start Monday Morning. The Entire Force was Laid Off and the Work will Be Pushed to Completion As Rapidly As Possible", Wayne County Democrat, p. 3.

- March 07, 1906: "Many Hogs For Bristles: Wooster Industry Imports Thousands of Dollars Worth From China and Russia", Wayne County Democrat, p. 1.

- July 04, 1906: "Wooster Brush Works Starting Fast on New Year", Wooster Republican, p. 2.

- September 26, 1906: "Fine New Office H. H. Miller Has the Contract for Construction of a Fine New Office for Wooster Brush S. Market street vacated by Photographer Osborne", Wooster Republican, p. 7.

- May 15, 1907: "J. E. McFarland Expert Machinist Built the Highly Successful Combing and Assorting Machines for Wooster Brush Works", Wooster Republican, p. 2.

- January 13, 1908: "Granted Patent On New Paint Brush: Wooster Manufacturer Place the Ohio Brush on the Market With Great Success", Wooster Daily News, p. 0.

- December 16, 1908: "Big Force Employed: By Brush Works Necessity of New Factory is Evident", Wooster Republican, p. 10.

1910s

- August 22, 1910: "Made Frushes All His Life: Oliver Foss, Who Helped Found Large Industry in Wooster Passes Away", Wayne County Democrat, p. 1.

- February 17, 1917: "Walter D. Foss with Merchants in Cuba", Wooster Daily Republican, p. 123.

1930s

- December 16, 1936: "Wooster Industries' The Wooster Brush Co." by Arthur Gossard, The Daily Record, p. 12.

1940s

- February 04, 1948: "Makes Three Millionth Brush", The Daily Record, p. 8.

1950s

- January 25, 1951: "Young and Vigorous", The Daily Record, p. 0.

- January 29, 1951: "Words of Thanks Appreciated By Wooster Brush Co." by Walter R. Foss, The Daily Record, p. 0.

- November 06, 1952: "Miss Elma Shibley Is Honored By Wooster Brush Co. For 50 Years of Service...", The Daily Record, p. 8.

- September 08, 1953: "Wooster Brush Began 102 Yrs. Ago By Foss", The Daily Record, p. 0.

- May 27, 1955: "Explosions Mean progress At Wooster Brush Co.: Better Nylon Brushes, Larger Roller Dept. Are Advances", The Daily Record, p. 0.

- January 25, 1958: "Eight Retire After Long Service With Brush Co.", The Daily Record, p. 0.

- May 02, 1958: "Brush Co. Honors Worker Service", The Daily Record, p. 0.

- June 21, 1958: "Wooster Brush Company 108 Years Old And Grows With Its Community", The Daily Record, p. 0.

- October 25, 1958: "Wooster Brush Had 105th Service Awards Banquet", The Daily Record, p. 10.

1960s

- January 12, 1961: "Wooster Brush, 110 Years Old, Honors Its Long-Term Employees", The Daily Record, p. 1E.

- June 30, 1962: "Wooster's Brush Business From a Box: Roller Is New Rival To Bristles", The Daily Record, p. 0.

- June 23, 1963: "Wooster Brush, Expanding Rapidly, Began With an Idea" by Guy Richard, The Daily Record, p. 0.

- October 14, 1965: "Brush Co. Bucket Is A Winner", The Daily Record, p. 0.

- December 13, 1965: "Expanded Wooster Brush Wins Month's ABC Award", The Daily Record, p. 19.

- October 21, 1967: "Wooster Brush Co. Honors Foss For 48-Year Stint", The Daily Record, p. 0.

- November 08, 1967: "Wooster Brush Co. Story One of Phenomenal Growth" by Guy Richard, The Daily Record, p. 0.

- August 07, 1968: "Wooster Brush Is a Success Because Employees Have Cared" by Freeman Long, The Daily Record, p. 0.

- November 08, 1968: "Wooster Brush Plans Plant Expansion In Nevada, Ohio", The Daily Record, p. 0.

- April 28, 1969: "Wooster Brush, Largest Of Its Kind, Grew From Adam Foss' Mystery Box" by F, The Daily Record, p. 0.

1970s

- August 14, 1970: "$750,000 Brush Co. Offices Are Built", The Daily Record, p. 0.

- March 24, 1975: "Wooster Brush Starts on Its 125th Year As Local Industry" by Elinor Taylor, The Daily Record, p. ?, 29.

- March 06, 1976: "Wayne County... Yesterday" by Elinor Taylor, The Daily Record, p. 19.

1980s

- June 09, 1987: "Wooster Brush Undertakes A Major Expansion Project" by Paul Locher, The Daily Record, p. 0.

- June 10, 1989: "Wooster Brush Men Home From Beijing" by Elinor Taylor, The Daily Record, p. A3.

1990s

- January 29, 1991: "Newly Redesigned Wooster Breush Packaging Highlights The City's Name", The Daily Record, p. 123.

- January 27, 1995: "Wooster Brush Poised For Major Expansion", The Daily Record, p. 0.

- January 05, 1996: "15th Wooster Brush Expansion Is Biggest Yet" by Jane Bablak, The Daily Record, p. 0.

- February 08, 1999: "Brush With History", The Daily Record, p. 0.

2000s

- February 24, 2000: "This 'Shortcut' pays big dividends: The Shortcut brush with flexible handle is smash hit for Wooster Brush" by Jim Thomas, The Daily Record, p. 4.

- July 02, 2000: "Doing it the Wooster Brush way", The Daily Record, p. 0.

- July 01, 2001: "Wooster Brush throws a party and invites a city", The Daily Record, p. 0.

- March 18, 2001: "Wooster Brush marks 150 year", The Daily Record, p. 1-2.

- March 20, 2005: "Wooster Brush honors employees", The Daily Record, p. 0.

- March 25, 2007: "Wooster Brush Company hands out service awards", The Daily Record, p. 0.

- September 06, 2007: "Stanley Welty Jr.", The Daily Record, p. 0.

- August 10, 2008: "From bristles to brushes, Foss brothers set up shop on East Liberty" by Paul Locher, The Daily Record, p. 0.

- August 20, 2008: "Fuzz ignites in pipe, causing small fire at Wooster Brush" by Chris Kick, The Daily Record, p. 0.

- November 02, 2008: "Wooster City Mills was a large employer, second to Wooster Brush" by Paul Locher, The Daily Record, p. 0.

- March 15, 2009: "Wooster Brush honors long-time employees", The Daily Record, p. 0.

- June 11, 2009: "Wooster Brush feeling effect of economic downturn" by Bryan Schaaf, The Daily Record, p. 0.

- Wooster Brush Keeps Firm Grip on Innovation- Founded in 1851, Company Maintain Close-Knit Ties in Difficult Times. Paul Schleis. Akron Beacon Journal. 2009. December 20, p. D1.

- History of Wooster Brush. Akron Beacon Journal. 2009 December 20, p. D3.

2010s

- January 24, 2010: "Wooster Brush applies for grant toward recycling program" by Bobby Warren, The Daily Record, p. 0.

- March 21, 2010: "Wooster Brush honors employees with service awards", The Daily Record, p..

- July 30, 2010: "Rodd retires from Wooster Brush; Fagert is new president", The Daily Record, p. 0.

- March 23, 2011: "Wooster Brush honors staff", The Daily Record, p. 0.

- March 18, 2012: "Wooster Brush honors long-time employees", The Daily Record, p. 0.

- February 2, 2013: "Wooster remembers Woodrow Zook - 'Gave his all' at Wooster Brush" by Bobby Warren, The Daily Record, p. 0.

- United States: CFI in Deal with Wooster Brush Company. TendersInfo News. 2012 July 27.

- March 17, 2013: "Wooster Brush honors longtime employees", The Daily Record, p. 0.

- March 15, 2014: "Wooster Brush honors longtime employees", The Daily Record, p. 0.

- U.S. Patents Awarded to Inventors in Ohio (April 22). Targeted News Service. 2014 April 22.

- June 22, 2014: "Wooster Brush fitness option has giddy-up and go result - Employees giddy-up and go, logging 10,000 hours of exercise in four months" by Bobby Warren, The Daily Record, p. 0.

- The Wooster Brush Company Granted United States Patent for Flow-Thru-Liquid Coating Applicator. Global IP News.2014 August 2.

- The Wooster Brush Granted Patent for Extension Pole with Reversible Tip Assembly. Global IP News. 2014 November 5.

- U.S. Patent and Trademark Office Releases The Wooster Brush's Patent Application for Tool Holder. Global IP News. 2014 December 19.

- The Wooster Brush Company Submits Canadian Patent Application for Tool Holder. Global IP News. 2015 January 21.

- The Wooster Brush Company Enhances WoosterBrush.com . Close-up Media. 2015 June 12.

- March 15, 2015: "Wooster Brush Company honors long-time employees", The Daily Record, p. 0.

- US Patent Issued to The Wooster Brush on Sept. 29 for "Universal Brush and Tool Holder" (Ohio Inventions). US Fed News, 2015 September 30.

- Wooster Brush Releases New American Contractor Paint Roller 3-Pack. PR Newswire. 2015 December 16.

- December 20, 2015: "Wooster Brush teams with Habitat for Summit County home work - Company gives brushes, rollers, labor in corporate citizenship act" by Tami Mosser, The Daily Record, p. 0.

- Wooster Adds Super-Doo-Z & Golden Flo items to Jumbo-Koter Program. PR NEwswire. 2016 January 26.

- February 14, 2016: "Wooster Brush celebrates commitment, stability - Wooster Brush paints picture of success 165 years strong" by Tami Mosser, The Daily Record, p. 0.

- February 25, 2016: "The Wooster Brush Company is 165 years young", The Daily Record, p. 0.

- Don Kosir celebrates 50 years with Wooster Brush. PR Newswire. 2016 March 3.

- March 20, 2016: "Wooster Brush pays tribute to 84 employees", The Daily Record, p. 0.

- New Wooster Brush Micro Plush Line Grows. PR Newswire. 2016 July 22.

- August 20, 2016: "Wooster Brush recognized by secretary of state's office" by Bobby Warren, The Daily Record, p. 0.

- September 23, 2016: "Paint brushes across America" by Ann Gasbarre, The Daily Record, p. 0.

- Wooster Brush adds three new Jumbo-Koter Minroller Kits. ThomasNet News, 2016 October 6, p. 39.

- Wooster launches Professional Gold Edge Paintbrush Line. ThomasNet. 2016 December 15, p. 9.

- February 23, 2017: "Locally making the finest painting tools for 108 years", The Daily Record, p. 0.

- March 19, 2017: "Wooster Brush Company celebrates its Service Awards", The Daily Record, p. 0.

- Wooster Renew Paintbrush Encourages DIY Painters to "Love Your Space". PR Newswire. 2017 April 11.

- Wooster adds Micro Plush 3-Pack to Micro Fiber Roller Line. PR Newswire 2017 April 28.

- Wooster Brush, Wooster, Ohio assigned patent for Locking Mechanism for Telescoping Members. Targeted News Services. 2017 May 18.

- Wooster adds four Semioval Angle Sash Paintbrushes to Silver Tip Line. PR Newswire. 2017 May 26.

- New 9-inch Wingnut Frame for Wooster Roller Gauges. ThomasNet 2017 June 20, p.26.

- Big Ben Tray Liner comes with integrated roll-off area. ThomasNet 2017 August 19, p.1.

- Wooster Brush assigned patent for Roller Cover. Targeted News Service. 2018 February 9.

- March 18, 2018: "The Wooster Brush Company celebrates 2018 Service Awards", The Daily Record, p. 0.

- June 22, 2018: "Bits and Pieces: Wooster's War Effort" by Ann Gasbarre, The Daily Record, p. 0.

- August 31, 2018: "Wayne Manufacturing Day among nation's largest", The Daily Record, p. 0.

- Wooster Mini-Koter Line Gets a New Look, New Items. PR Newswire. 2018 October 1.

- Latest Mini-Koter Minirollers are suitable for painting in tight areas. ThomasNet. 2018 October 3, p.4.

- October 06, 2018: "Future Possibilities: More than 600 students explore career options with 16 companies" by Linda Hall, The Daily Record, p. 1.

- Wooster announces expansion of exclues Wooster pro product offering at Home Depot. Datamonitor. 2018 November 6, p.

- New Ultra/Pro Firm Paintbrush Lines provide improved tipping process to reduce drag. ThomasNet 2019 March 25, p.

- Wooster Brush paints a long history and is primed for more. Bob Sandrick. Crain's Cleveland Business, 2019 June 24, p. 24.

- The Wooster Brush Gets Patent for Pipe Painter Assembly. Global Ip News. 2019 August 7.

- Wooster Brush announces Cirrus X. Datamonitor. 2019 September 23.

- The Wooster Brush Company launches bold new look. PR Newswire. 2019 November 1.

- Wooster Brush assigned patent for Roller Cover an Associated Cams. Targeted News Service. 2019 December 12.

2020s

- April 09, 2020: "Wooster Brush Co. names new president" by Jack Rooney, The Daily Record, p. 1.

- Wooster Brush Company announces 2020 Service Awards. Daily Record. 2020 April 26.

- Wooster Brush assigned patent for paint brush with grooved plug strip. Targeted New Service. 2020 April 30.

- United States Broom, Brush and Map Market 2020-2025, Featuring Key Vendor Profiles for Weiler Corporation, Felton, Tne Libman Company and Gordon Brush Mfg. Co. PR Newswire. 2020 August 10.

- December 28, 2020: "Longtime businesses give survival advice - Friendly Wholesale Co. attributes success to customer service and dedicated employees" by Samantha Ickes, The Daily Record, p. 123.

- March 17, 2021: "Wooster finds first tenant for industrial park" by Emily Morgan and Linda Hall., The Daily Record, p. 123.

- March 26, 2021: "Wooster board OKs Wooster Brush abatement" by Linda Hall, The Daily Record, p. 123.

- April 07, 2021: "Abatement for Wooster Brush Co. site approved - Wooster City Council Monday, April 5 meeting" by Bryce Buyakie, The Daily Record, p. 123.

- April 11, 2021: "Distribution warehouses in the works for Wooster" by Bryce Buyakie, The Daily Record, p. 123.

- April 25, 2021: "Wooster Brush Co. gives out 2021 awards", The Daily Record, p. 123.

- May 20, 2021: "Maibach scores chamber's leadership award", The Daily Record, p. 123.

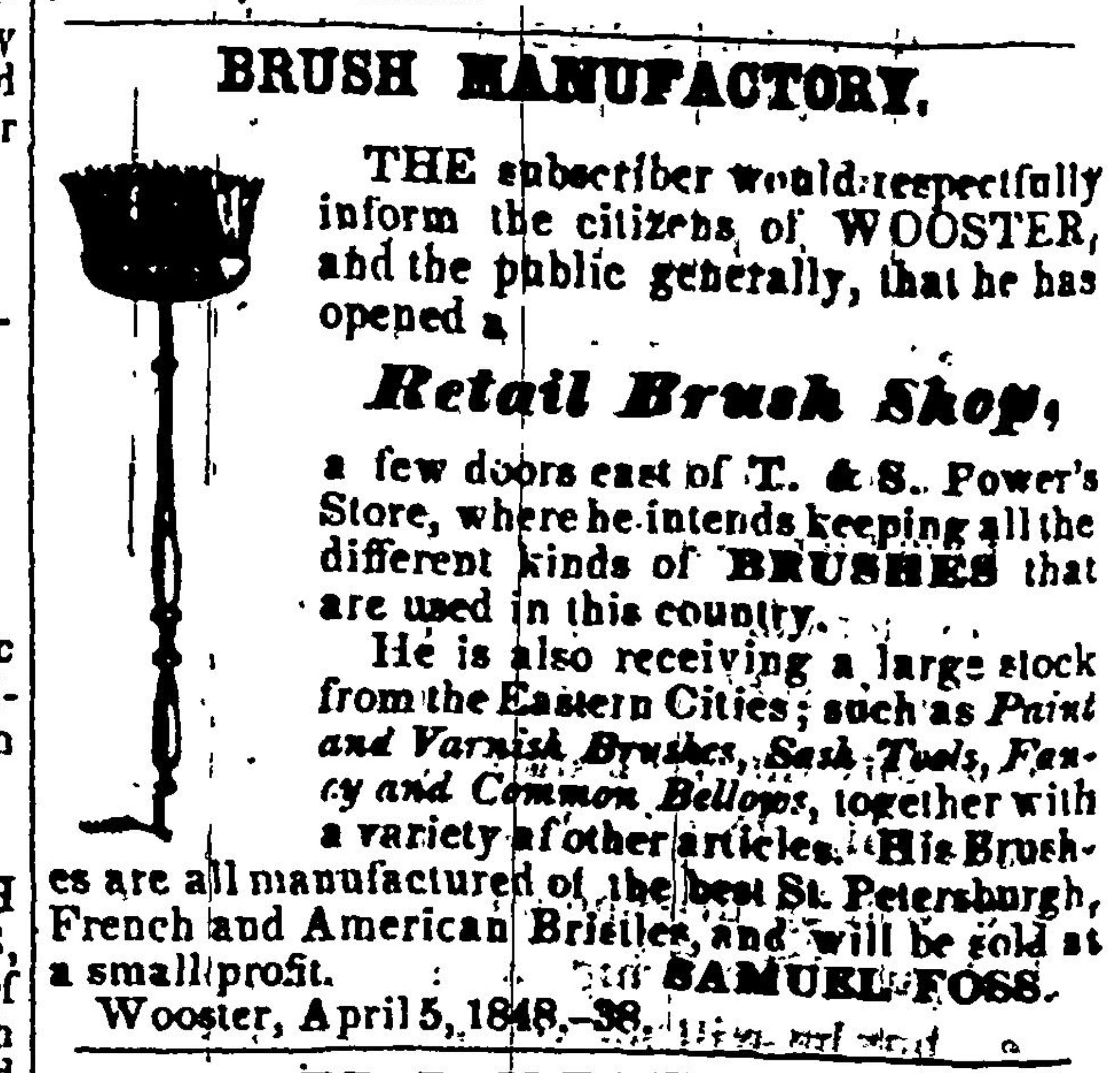

Newspaper Full Text & Clippings

Wooster Brush Factory - A Foss' Brush Factory

The prosperity of our city depends much on the hearty support of our home industry, which can be done in part by calling at A. Foss' Brush Factory, one door north of the Post Office, where he will be found, on the second floor, with a good assortment of Brushes. He pays no rent, and can therefore sell cheap.

He manufactures White wash Brushes, Moulders' Brushes, Horse Brushes, Shoe Brushes, Stove Brushes, Dusting, Fancy and Common Brushes, Mill Brushes, Printers' Lye Brushes, Tanners, Tumbler, Window, and Paint Plastering Brushes. Brushes for special purposes and Machine Brushes made to order at wholesale and retail. [1]

A Visit To The Wooster Brush Works: An Institution That Never Shuts Down, But is Kept Busy All the Year

"How's business with the Wooster Brush Works?" was asked of Mr. Geo. J. Schwartz, of the enterprising firm of Foss & Schwartz, as he was giving orders to a shipping clerk yesterday morning.

"Very encouraging" was the terse but emphatic reply. He thereupon settled himself upon a box containing a $250 order ready to be shipped to a Pennsylvania patron, and pointed to any easy chair which the writer was not long in tilling.

"Yes, we have been having a splendid trade for the past two years," he continued "Although we work from 7 a.m. until 10 p.m., nearly every day, we are far behind with our orders. We have just added nine to our working force. Two are experts from Baltimore. One of them turns out 100 dozen oval point brushes in a week and the other, with the assistance of two boys, 75 dozen of whitewash brushes in the same length of time" When asked the SECRET OF THEIR SUCCESS, Mr. Schwartz said, "We are supplying the trade with nothing but first-class goods and furnish them at prices as low as any factory can supply them in the United States. We buy our bristles in the raw material, direct from Russia and France, with seals of the government unbroken at any port. We could buy our material already prepared from Eastern houses at as low a figure as we could do it ourselves, but there is danger of having it mixed with an inferior quality. Two years ago we built a bleaching house at the rear of the factory. Come along and I'll take you through it" The writer was then led to the rear of the factory to the bleaching house a long brick building. We boil the bristles in this porcelain vat" he said pointing to a large cauldron suspended over a furnace, after which they are thoroughly rubbed and rinsed . They are then removed to the bleaching room proper, at the rear end of the building. Here they are arranged on racks. This room is practically air tight. At night we fill a vessel with brimstone-- about 15 pounds and place it beneath the racks. A hot piece of iron is thrust into the brimstone and the door quickly closed. By morning the fumes of the brimstone have bleached the bristle to a lily white color. They are now tied into little bunches and placed in the drying kiln. They are next combed and afterward assorted into lengths by our process of bleaching, THE LIFE OF THE BRISTLE is retained longer than stock prepared by Eastern manufacturers.

"Just notice the elasticity of that brush" interposed Mr. W. D. Foss, of the firm, who stepped up at this juncture, picking up an 8-0 oval paint. The writer having been at one time a practical painter is naturally a connoisseur of such brushes. Knowing that after the life or elasticity of the bristles is gone that the brush is worthless, he saw at a glance that the one handed to him was of a superior quality and capable of being worn close to the ferrule.

"Do you manufacture all the goods you place on the market?"

All but tooth and hair brushes. We manufacture six grades of oval paint brushes and nine of flat wall paints, live grades of calcimine and seven of whitewash brushes. Of the latter the prices run from $150 to $60 per dozen. In horse brushes we manufacture 40 different grades, the prices running from one dollar to $60 per dozen. We are having a great run in the horse brush department. In cloth, shoe scrub and stove brushes, etc. we have a like number of grades. We are constantly adding new machinery to our factory and increasing our facilities. We are now enabled to turn out any brush manufactured of a regular or special design.

HISTORY OF THE FIRM

The Wooster Brush Works had its inception in 1851, when Adam Foss established a small factory on East Liberty street, opposite the Home Mills. Several changes in location were made until finally in 1875 the present location at No. 35 South Market St., was purchase. In the factory's early history, Ohio trade was particularly sough. Traveling in soliciting orders had to be done by wagon, owing to the limited railroad facilities. In 1876 Mr. A. Foss retired having sold the factory to his son, Walter D. Foss and son-in-law, George J. Schwartz. The young men entered upon their duties with great zeal and enthusiasm. By reason of indefatigable energy of the young men in conjunction with the wise counsels of former proprietor of the factory, Mr. A. Foss, the trade soon branched out into States adjacent to Ohio.

On January 27th 1879, however, the "young blood" was chilled by the destructive fire that wiped out the entire block. In addition to a clean loss of $10,000, the spring trade, the cream of the year, was also ruined with commendable pluck, however, they removed what little machinery and stock was saved from flames to the Curry Block on East Liberty street They contracted with Eastern manufacturers and were thus enabled to fill the orders on hand. By the following October, a handsome three story brick stood on the site of the old factory into which they at once moved. Since that time their trade has been steadily drifting further to the east and west. They have at the present writing six men on the road, and have established a good trade in Ohio, Pennsylvania, New York, West Virginia, Indiana, Illinois, Michigan, Wisconsin, Missouri, Iowa and Kansas, In the latter state they have a resident agent stationed at Topeka.[2]

Wooster Brush Works (Puts in New Engine

Wooster Brush Works has put in a new engine, as the whistle announces morning, noon and night. The plant has been remolded and a new building added which contains the engine. Miss Jennie Kelly has been employed as stenographer. [3]

Wooster Booming

... It may be matter of surprise to many of our readers, to citizens of our city and county that Messrs Walter D. Foss and George J. Schwartz of South Market street, are largely engaged in the manufacture of brushes and are meeting with the success which attends indomitable business energy, when united with conscientious stride in maintaining the excellence of the work produced.

The original brush works of Wooster were started by Adam Foss in 1851, who, for over a quarter of a century, prosecuted their manufacture in a modest yet energetic way. His son-in-law, Mr. Schwartz, in the later years of Mr. Foss' business activity, became his partner, under which management the business satisfactorily prospered, when his son, Walter D., purchased his interest in 1876, the firm thereafter being known as Foss & Schwartz, when a new and more ambitious life was communicated to the concern. Thoroughly understanding the business, both having practical and mechanical knowledge of it, they determined to occupy no second place in their field of industry. They resolved that the work they did do should be well done, and that they would manufacture the best and latest stylist;es of brushes.

The rewards of their persistence and energy in a few years spun around through the channels of trade to their pockets, and, in ____, a fine new three-story brick building, with commodious under apartments, took the place of the old frame structure. The building is most favorably located, in close proximity to the public square, having all the facilities for the work in hand-- except in its capacity-- the temperature of the entire building being regulated by hot water process.

On the first floor are cases for the exhibits of their products in their different kinds and styles, the accountant's apartment and the salesroom, and here the assorting, packing boxing and preparations for shipment are transacted. The rooms on the second story are the manufactory proper. Here the products of the different skilled workmen employed are finished, under the masterful foremans tip of William Unger, who makes regular reports of the condition of stock and supplies and the efficiency of the labor employed under his supervision. From this department the work goes to the third story, or finishing and painting rooms, when it is transferred to the salesrooms below.

They find ready market for all of their manufactures-- and they make everything in the line of paint brushes that paint and ____ houses buy or sel--their orders constantly crowding them to the extent that they are unable to fill them to suit the pleasure of the jobbing establishments that desire their goods. At this time they have orders amounting to $25,000 from various sections of the United States, from California to New York and which they are filling as promptly and rapidly as possible. With the present outlook they are assured the shipments for 1893 will triple those of any preceding year. Five active, energetic men represent them in the field assignments of territory being made of each a specified number of States for canvas and sales. Their consignments are surprisingly large, to the Southern States, especially Georgia, Tennessee, Alabama, Kentucky, Missouri, etc., and they are satisfactorily so in the West and North, from the Pacific coast to New York. In Ohio, we were informed by one of the partners, they sold more brushes than any other manufacturing concern in the United States. In our meander through the building we saw boxes labeled Los Angeles, Oklahoma, Huntsville, Ala., Carthage, Mo., Buffalo, N. Y., etc., in answer to orders ranging from $300 to $800, chiefly from the larger houses who want to job their goods. Everywhere around us, in the cellar, on first, second and third floor, boxes, shelves and drawers filled with stock and supplies were to be seen, and machinery and apparatus to expedite and perfect work was humming or ready to hum. There was unfinished stock in abundance, brush sewing appliances, brush frames from Corry, Pa., and Massachusetts "ferls" impending from the ceilings, walls and racks by thousands, piles of costly leather, boxes and bins of bristles, with their Chinese and Southern American substitutes for cheaper work, barrels of glue, paint, varnish, etc., etc., all live assurances of thrift, business snap and solid prosperity.

For their best and most durable brushes they use the bristles of the hog, the best quality being obtained from the wild species of the north of Europe, Russia contributing the major proportion to the market. These animals have usually acquired some age before they are killed, as it the case with the domestic Russian hog, which is slaughtered more for its grease than for food for the table, and the fact of age in both instances furnishes a stiffer and consequently a more valuable, and also, a more expensive bristle. The firm buys the bristles directly from eastern and London importer which are bound in rolls of various sizes and boxed for transportation. When they are received they must go through an elaborate process of cleaning, having to be washing, bleached and dried. Other material is used than the bristles of the hog for horse brushes and the cheaper grades, such as horse hair, sea grass, tampico, rice root, kitool, etc,

The reputation of their work is established, and is not surpassed in the United States, which declaration is confirmed by the admissions of rivals in the trade and the wide market they are unable to supply with their products. The original founder of the house, Mr. Adam Fox, now in serene and healthful retirement, remarked that he "had been in the business for forty years, and that forty years' more experience in it would not enable him to master it"-- that it required skilled and honest hands to make a good brush. And it is due to Messrs. Foss & Schwartz to say, in the organization of this industry they have not only had the counsel of its founder, but that they have aimed to employ only such workmen as can be implicitly relied on, who have, like themselves, and industrial conscience and a pride in the result of their labor. [4]

Brush Works Let Contract - Large Factory to Be Completed in June - Largest Brush Works in World

The Wooster Brush Works, Walter D. Foss & Sons Co., let the contract Monday to Wm. H. Long, for the erection of their new Brush Factory, at the intersection of Madison Ave., and the Pennsylvania Ry. Co. The main building will be 70 feet wide by 200 feet long, of brick and cement, three stories, slow burning construction, with a heating and power plant at the rear, 25 feet x 70 feet, one story. They will have their own railroad, side track, from the main line of the Pittsburgh, Ft. Wayne & Chicago Ry. A Sprinkler System for fire protection will be installed--the elevated gravity tank for same, 16 feet in diameter by 20 feet in height, with a capacity of over twenty five thousand gallons, and weighing , when full of water, over one hundred thousand pounds, will be placed on top of the elevator shaft, the bottom of tank will be twenty feet higher than the highest sprinkler head. This modern fire protection, it is expected, will reduce their insurance rate about 60 to 65 per cent. The contract calls for the completion of the factory by June first. Work benches, will be provided at present for two hundred employees, and with these increased facilities, modern equipment as to machinery of all kinds including their own machine shop for making necessary repairs, they expect to be able to double their present output.

Their present force of about one hundred employees in both factories at No. 35 and 56 South Market street, working over time three nights a week, are unable to keep up with the orders, which are being received daily from all sections of the United States, and from the very largest brush buyers in the country, which is evidence that their high quality brushes are being sold at prices that are satisfactory to the buyer. Provisions are being made for the addition of another story or two should their necessities require same. They will continue to operate the two old factories to their full capacity until the new buildings are completed.

This will be the largest manufacturing building, and will employ more employees than any in the city at the present time. W. D. Foss in speaking to a News reporter, Monday, stated that he believed that this building was the first one every built as a brush factory. Other brush companies have either bought or leased buildings formerly occupied by other manufacturing interests and as a consequence, this factory will the most model one in the country. Wooster heartily congratulates the Wooster Brush Works Company on their enterprise. [5]

The Wooster Brush Works

Business Established Over Half a Century Ago Continues Through Three Generations.

The Wooster Brush Works was established by Adam Foss in 1851 in a small room on the third floor of the building now known as the Bashford building on the east side of the public square.

The founder was succeeded by his son, Walter D. Foss, and George J. Schwartz, in 1876, who carried on the business in the two story frame building known as the Hine property at No. 35 S. Market St.. This structure was completely destroyed by fire, of an incendiary origin, on the night of Jan. 29th, 1880. and the loss sustained on the stock by the young business men was severe, they having carried but a small insurance. However, while the debris was still smoking they immediately ordered stock, machinery, etc., and opened for business within a week in a frame building adjoining Wilhelm's Carriage Factory, now Clapper's Factory,

on East Liberty St., remaining at this location during the summer of 1880 until the substantial three story brick building erected by Samuel Geitgey, Adam Foss, and Messrs. Logan & Myers, on South Market St. was completed. For a few years thereafter, Messrs. Foss & Schwartz occupied only the first and third doors of the middle part of this building, the Wayne County Mutual Insurance Company using the second floor. However, it was not long until the Brush Company needed the the entire building, and the Insurance Company was compelled to see another location Then in 1893 an addition was built at the rear of No. 35 South Market St., doubling the floorspace.

July 1st 1904, the partnership was dissolved, Mr. Schwartz retiring, and Walter D. Foss & Sons' co. continuing the business under the old firm name of Wooster Brush Works.

In April, 1906, Walter D. Foss resigned as president of the Citizens National Bank, so as to enable him to devote his entire time and attention to the Brush Company., and in February 1907 he purchased the south half half of the three story brick building known as the Foss & Lee Block, No. 56 South Market Street, and the Flat Varnish and Artists Brush departments, as well as the offices of the works, were moved into the new building, electric light and power being transmitted from the main factory, where the manufacture of what are known as heavy lines of brushes, such as Paint, Varnish, Whitewash and Kalsomine brushes, etc. was continued.

But even with these increased facilities they were unable to keep pace with the rapidly growing demand for their products, the business having more than doubled during the past few years, making the building of an entire new factory with ample floor space imperative.

The Engineering Company, of Cleveland, who are the leading architects in northern Ohio in the construction of industrial plants, were instructed to prepare plans for a new factory to be located at the intersection of Madison Avenue and the Pennsylvania Railroad. The main building is seventy feet wide, by two hundred feet long, three stories, with a heating and power plant at the rear twenty-five feet by seventy feet, one story. The entire structure, contains three times as much floor space as they had in both the old factories. The general contact for the new building, as illustrated above. was let on March 1st, 1909, and with this equipment they are manufacturing one thousand dozen brushes per day.

The most significant proof of the modern construction and up-to-date equipment of their plant is the fact that they enjoy a lower fire insurance rate than any other Brush Factory in the world.

They own and control a number of patents in the Paint and Varnish brush lines which have revolutionized this industry, not only in this country but in most foreign lands. [6]

1917

Wooster Brush, Expanding Rapidly, Began With An Idea

It is inconceivable what an idea can grow into if conceived by a man with ambition and the will to win. Such an idea was born in the mind of Adam Foss in the year 1851, and the results are providing a comfortable living for hundred of people in Wooster.

The story has been told, but bears repeating, as several thousand persons have moved into our community since the "Century Celebration" of the Wooster Brush Company occurred about twelve years ago.

Fabulous stories of this type bear repeating, as they may be an incentive to some young person who may be wondering just how he is going to make a living in this hard-boiled world, especially while a multitude of recent commencement speeches are still ringing in his ears.

From what we can learn, Adam Foss was an average young man, but possessed of that spark of initiative genius, backed up with a super abundance of stick-to-itive-ness that spells the difference between failure and success. Luck may have entered into the picture.

In 1840, Foss was walking from Pennsylvania to Cincinnati, and it must have been sheer luck that he wandered into a Cincinnati Express Office, where he bought an unclaimed package, (a pig in a poke) which happened to contain hog bristles.

Here is where Adam Foss graduated into a genius, as the average man would have tossed the bristles in the first alley he passed, with the words not acceptable to our Editor.

PLAYS HUNCH Adam Foss played a hunch. Mr. Foss was also resourceful, so he whittled out handles and blocks, glued the bristles in place, and found a ready market for his product as he traveled from house to house.

At the age of 29 he started his first plan on Liberty St., which afterward moved to South Market St. in the building now occupied by the Schrader Hardware Company, where he operated as the Wooster Brush Works, which has grown to be one of the three largest brush manufacturers among the 37 plants in the United States.

Adam Foss peddled brushes from house to house in Wooster. In 1876, he sold his factory to his son Walter D. Foss, together with a son-in-law George J. Swartz, whose former homes still stand on North Market Street. The Foss home is occupied by Marie Schafter's law offices and the Swartz residence immediately south was sold at auction on June 21 to the E. L. Buehler Company.

NOW INCORPORATED A few years later W. D. Foss, his eldest son Oscar H. and Louis M. Rhodes bought Mr. Swartz' interests. And in 1909 the business was incorporated under the laws of Ohio and became known as "The Wooster Brush Company," as it is known to-day.

The shares are closely held, principally by employees, former employees, or heirs of employees. Space does not allow the names of all persons in the line of succession who have guided the destinies of this Company. The sons in order of their age were: Oscar H., Don J., Clifford P. and Walter R. The boys have one sister Mildred Thompson who lives in Boston, Massachusetts.

The personnel or labor relations of this company have been second to none in the United States. They never waited until they were forces to install "hidden pay" benefits such as profit sharing bonus, life insurance, (paid by the company) paid vacations, employees relief association, and others in addition to all compulsory benefits.

BENEFITS HIGH A report from the Chamber of Commerce of the United Stated published in 1950, states that the Wooster Brush Company workers annual benefits average $874 per year, or forty-three cents per hour. However, since 1950 they have adopted a retirement pension plan that will increase these benefits.

While Adam Foss' initiative provided the nucleus for this outstanding Company, were it not for Walter D. Foss, father of the third generation of Foss', and the unusual business acumen and devotion to maintaining the highest quality of brushes, as carried on by his sons, the business could not have grown to its present proportions.

The co-operative spirit of these sons is exemplified in their ability to select people of the highest type to assist them in climbing the ladder to success.

As the older sons retired or died, they went outside their immediate family to select a President in the person of Stanley Welty. The business has grown remarkably under the guidance of Mr. Welty, as he in turn surrounded himself with the highest type of personnel. Walter Foss, Chairman of the Board has served the Company for 44 years in various capacities, and has been a chief factor in their phenomenal growth in recent years.

Woodrow Zook serves as vice-president treasurer and secretary and has capably filled all three positions. Much credit must be given to John G. Zapf, vice-president in charge of sales, Forest Shaw, vice-president in charge of manufacturing and Robert Bunn, who has the responsibility of procuring raw materials.

RECENT INNOVATIONS Recent Innovations which occurred in the painting business have caused revolutionary changes in brush manufacture. Paint rollers, nylon bristles, plastic handles, etc. have necessitated the installation of modern and high prices machinery. The popularity of their products have forced them to enlarge their plant by the addition of fifty thousand square feet in order to supply their customers.

Wooster is very proud of a company which has maintained the highest quality and shipped their products all over the world. The Foss family has helped in a large way to make Wooster what it is, one of the finest communities in which to live. [7]

Wooster Brush is growing ... again: Huge machines to stamp out paint trays ad roller parts will fill Bever Street expansion

WOOSTER -- There's an old joke around town that at its present rate of expansion, the Wooster Brush Co. will eventually be all around the town.

And for the better part of a century the huge paint applicator business that is one of the oldest industries in continuous operation in the county has been growing and sprawling ever farther north and northwest of the site it bought on Madison Avenue in 1909.

The company is putting the finishing touches on a 30,000-square -foot addition that brings its total amount of owned manufacturing, warehousing and office space in the community to 530,000 square feet.

Even with that, however, the company is still leasing off-site warehousing of production materials.

Bob Ricksecker, advertising manager, said the new addition on the southeast corner of the South Buckeye and Bever Street intersection will be used to centralize metal fabrication operations for the facility.

The space is now dominated by a huge press that will be used to stamp out 11-inch square steel trays that will hold paint for roller application.

Metal coils weighing 6,000 pounds each will continuously feed material into the press to create the stampings, which will be generated at the rate of one every three seconds.

As the newly formed trays come out of the press and down a conveyor belt, legs are welded to the bottom.

Dennis Humphrey, vice president of engineering, said the new addition and the equipment it will house represents a "significant investment" for the company, and added that the 300-ton forming press is considered state of the art in computerized metal bending.

Humphrey said the new press allows three previously separate machining operations to be consolidated. He noted that the new addition provides space for a number of metal machining operations to be brought into closer proximity for greater operating efficiency, as well as freeing up space in other areas of the plant. The company also does in-house production of its own roller handles and roller cages in various grades.

Humphrey said other machines housed in the new addition will be used to bend wire rod to the appropriate shape for a variety of paint rollers manufactured by Wooster Brush to serve what it perceives as an expanding market.

"The roller is becoming the instrument of choice for painters," said Humphrey, "so the roller business is an up and coming part of our operations."

He said that where once people tended to wash out rollers, faster-drying paints have made that more difficult to do, so people just throw them away and buy new ones.

In addition to the standard roller covers, which are 9 inches long and an inch-and-a-half in diameter, the company is developing a line of what Humphrey calls "mini-rollers," which are only 6 inches long and a half-inch in diameter. They are designed for use in cupboards, as well as in tight spaces like behind toilet tanks.

The Wooster Brush Co. is the only paint applicator manufacturer that makes its own painting trays. The company also manufactures all of its own roller covers and packaging and does its own graphics work, rather than sending it to an outside vendor.

Richsecker said the addition will have generally the same vertical concrete ribbed exterior appearance as the rest of the facility, with the exception of the corner at the Buckeye and Henry Street intersection, which will have brickwork and be decorated with the company's so-called "flying W" logo done in brass.

Almost like clockwork, Ricksecker said, the company has been building major additions every five years, and the expansion plans continue with the company purchasing residential properties near the plants as they become available.

Also recently the company doubled the size of its only owned off-site facility, a warehouse in Reno, Nev. [8]

Wooster Brush adding four levels

Wooster Brush Co. broke ground Monday for a nearly 27,000-square-foot addition to its downtown plant to house human resources, production control, engineering, graphic design and manufacturing management.

The addition will include four levels (three stories above the ground, plus a lower level) and is expected to be completed in about a year.

The project is the latest for Wooster Brush, which has grown steadily since opening in the community more than 150 years ago. Last year, the company put the finishing touches on a 23,5000-square-foot addition to accommodate its paint tray and roller frame operations.

Allan Rodd, company president, said in a released statement, "We have undertaken numerous expansions to our manufacturing and warehousing space over the decades. This addition is highly anticipated because it is the first for our office facilities since 1970. It is our latest effort to provide our employees an excellent work environment, which is conducive to our manufacturing the finest products in the painting industry."

Frank Beeson, president of the Wayne Development Council, said he had discussed expansion possibilities with Wooster Brush, but the company quietly finalized its decision. He said the expansion project would be a welcome addition to downtown.

"That's outstanding," Beeson said late Monday afternoon. "They're our oldest industry and continue to show us why."

The addition will be constructed in the courtyard space between Wooster Brush's office building and the factory building, which includes shipping, warehousing and the company store. The existing upper office courtyard and patio and the visitors' parking area off Buckeye Street will be replaced.

According to the company, the manufacturing office area at the southwest corner of Madison Avenue and Buckeye Street is a full capacity. The addition will provide "a better work environment and provide room for facility improvements and upgrades required by increased business needs," according to a company release.

The project is being coordinated by Bogner Construction Co., Christian & Klopper Inc. of Shaker Heights is serving as architect and structural engineer.

Wooster Brush Co. was founded in 1851, when Adam Foss began making hog bristle paint brushes inside a small two-story building. The company manufactures more than 2,400 products that are sold at retail outlets nationwide.

Wooster Brush has expanded more than 20 ties since operating in the original building, now located on the southern corner of a facility. The company employs more than 500 people.

With the addition, Wooster Brush's plant will have more than 554,000 square feet of operational space. [9]

Wooster Brush finalizes purchase of Crown building

WOOSTER -- Wooster Brush Co. finalized its purchase of the former Crown North America building.

The company told employees of the acquisition Friday, according to Bob Ricksecker, advertising manager. It plans to renovate the space for warehousing and distribution activities.

there are no immediate plans to increase the company's work force (Wooster Brush has about 600 employees). The 257,000-square-foot facility is located on 12.5 acres at 1654 Old Mansfield Road.

Wooster Brush's downtown facility, which includes more than 554,000 square feet of space, is land-locked, making physical expansions difficult. The Crown building, left vacant last year when Missouri-based Leggett & Platt transferred the local operations out of state, offered space to accommodate The Brush's growth.

Al Rodd, Wooster Brush president and treasurer, said in a release, "Purchasing the Crown building and property illustrated our commitment to this city and desire to grow here. During 153 years of business in Wooster, we expanded our original facility on Madison Avenue more than 20 times. Wayne County is an excellent place to work and live. We are proud to be one of several nationally successful manufacturers located in this area."

Leggett & Platt announced in November 2001 it intended to close the Wooster facility in early 2002, leaving more than 350 people out of work. However, production continued, on a lesser scale, through most of 2002.

An announcement released by the company in September stopped short of stating the plant would close permanently. Instead, the company called the move "a temporary idling due to the deteriorating market conditions in the telecom capital equipment markets te Wooster facility serves.

"(The decision to idle was) based on economic factors beyond the control of the employees and management of the facilities and is no reflection on their productivity and the quality of their products."

Wooster Brush signed a contract for the property in January, with the transaction contingent on an inspect of the building. The company plans to complete renovations at the building by this fall.

With the closing, the facility has been renamed "Wooster Brush Plant No. 2." [10]

Wooster Brush buys 43 acres in Bogner Business Park

WOOSTER - Wooster Brush Co. on Thursday announced intentions to purchase land in a business park that will develop at the end of Old Airport Road.

The company has a 90-day option on 43 acres in the Bogner Business Park.

When and if the transaction is finalized, the land will be used for expansion in a general, long-term plan yet to be developed, according to a release from the company.

"We're planning for the next 152 years," said Al Rodd, president and treasurer of Wooster Brush, as he stood at the land's entrance, looking voer the site in the heat and humidity of Thursday morning. "In five, 10, 150, 20 years we might build something here."

Ted Bogner, president of Bogner Construction Co., said his company and Wooster Brush have been in discussions since November. This is the first land purchase in the 130-acre park, which is zoned M-1 (limited manufacturing) per a cooperative effort with the City of Wooster and neighbors in the area of Melrose Drive, Bogner said.

"We have talked to no one" during discussions of the Wooster Brush transaction, Bogner said. "We were unsure just exactly how much acreage and everything they wanted, and (in) what condition."

He said the intent is to attract quality businesses into the park, and the company is beyond pleased to begin with Wooster Brush.

In the release, Rodd said, "Bogner Construction Co. has done business with us since 1909, when we built our first plant on Madison Avenue. They just completed our most recent expansion to our manufacturing offices this spring.

"We anticipate continuing our solid partnership with Bogner well into the future."

On June 13, Wooster Brush finalized the purchase of the former Crown North American Building on 12.5 acres along Old Mansfield Road, also with intent to expand into that building.

Rodd said the company will remain headquartered in town.

Utility improvements have begun on the land north from the cul-de-sac ending of Old Airport Road. The 43 acres is in the northern area of the business park.

"It's a tremendous piece of property," Bogner said. [11]

From Bristles to Brushes, Foss Brothers Set Up Shop on East Liberty

WOOSTER -- The Wooster Brush Co., today the city's oldest and one of its largest industries, actually started as the result of someone's buying a pig in a poke. And that's not just an expression-- it actually did start that way.

The business had its origins in an unusual purchase made by a man named Adam Foss, who at age 29, in 1851, migrated to Ohio from Lancaster, Pa. While visiting in the Cincinnati area, Foss attended an auction of unclaimed freight held by an express company.

Foss didn't know what he had purchased, but when he opened the large wooden crate, he found a shipment of hog bristles that had come from China. Uncertain what to do with its contents, Foss took the crate with him when he went to visit his older brother Samuel who lived in Wooster. The two brothers put their heads together on how to make some money from the bristles, and came up with the idea of turning them into brushes.

The Foss brothers set up a shop on East Liberty Street where The Daily Record is located today. There they made wooden handles to attach the hog bristles to, then went about the task of selling the first Wooster paint brushes door-to-door throughout the state. At the time the Foss brushes were superior to any others generally available and the duo quickly developed a customer base.

Distribution of Foss brushes slowly expanded throughout the state to accounts in Indiana, Michigan and Pennsylvania, with the brothers assuming the triple roles of brush makes, salesmen and business owners. In 1861, as the business expanded, the company moved to a slightly larger location on the southeast side of the public square, occupying the third floor above the Boyd Drug Store.

In 1876, Adam sold his share of the business to his son, Walter D. Foss. Together with a son-in-law, George J. Schwartz, they changed the name to Wooster Brush Works. In 1879, the growing operation with 30 employees moved to 35 S. Market St.

That same year Adam Foss retired as president of the company, dying in 1907 at the age of 85. On Jan, 1, 1904, Schwartz retired and the business was purchased by Walter, his eldest son, Oscar, and Lewis M. Rhodes, who laid the groundwork for today's operations. Source: Wooster Brush Co. history [12]

- ↑ Wayne County Democrat, Wooster, Ohio 1870 September 15.

- ↑ Wooster Republican, Wooster, Ohio. 1887 December 1, p. 4.

- ↑ Wayne County Herald, Wooster, Ohio. 1903 September 17, p.0.

- ↑ Jacksonian, Wooster, Ohio. 1893 Jan 26, p.3.

- ↑ Brush Works Let Contract. Wayne County Democrat, Wooster, Ohio. 1909 March 3, p.1.

- ↑ The Southwestern Way, Wooster, Ohio, p. 24-25.

- ↑ Wooster Daily Record, Wooster, Ohio. 1963 June 26, p.0.

- ↑ Daily Record, Wooster, Ohio. Paul Locher. no date

- ↑ Daily Record, Wooster, Ohio. Local News. 2002 March 19.

- ↑ Daily Record, Wooster, Ohio. by Marc Kovac Local News. 2003 June 13.

- ↑ Daily Record, Wooster, Ohio. Stephanie Kandel. Local News. 2003 July 5

- ↑ Daily Record, Wooster, Ohio. by Paul Locher. 2008 August 10 Local News, p.0.